Guides for properly installing our products

Below you will find some important information regarding the site preparation & installation of our bi-folding, sliding & rooflight products. Important things to bear in mind are the bottom track details of the doors.

Site preparation for the areas where the products will be installed, plus how to glaze the bi-folding doors correctly using the toe & heel method.

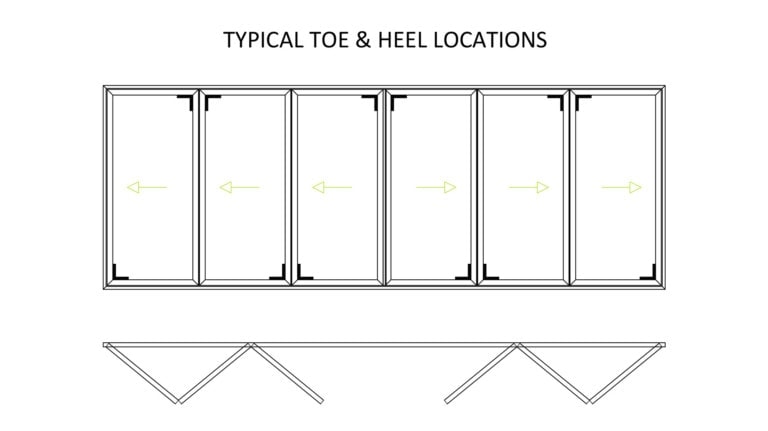

Toe & heeling a bi-fold door

Toe and heeling a bi-folding door is essential to ensure that it operates correctly. The principles of toe and heeling are the same for a bi-fold door as they are for traditional French doors. The reason the glass needs to be toe and heeled is because the weight of the glass in the door panels will causes it to drop and catch on the bottom track when the door is opened and operated. When we toe and heel, we are essentially using the glass to brace the door panel and to distribute the weight accordingly, so the glass supports its own weight.

Toe and heeling is always done in the bottom corner that is fixed to the runner and top corner that is diagonally opposite. This is repeated with every panel, so the glass needs packing in the bottom corner by the runner and the opposite top corner.

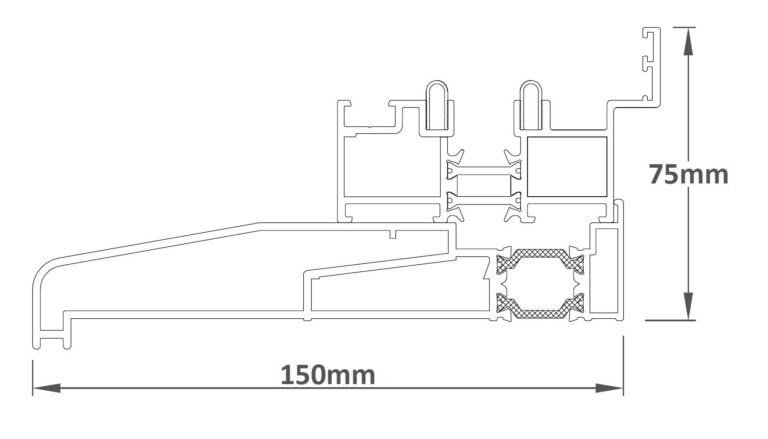

Rebated bottom track

We offer two different bottom track options for our XP10 bifold doors, both of which are sat on a 150mm external cill. The rebated bottom track option creates a proper weather seal as the door panel closes against the rebate. From the underside of the cill to the top of the internal rebate the measurement is 75mm so the internal floor level can be sat almost flush against the top of the rebate to create a seamless transition from inside to out with a flush internal floor finish.

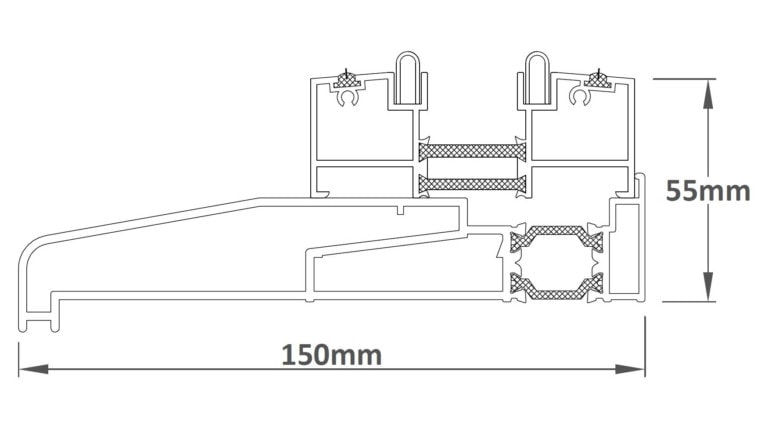

Low threshold bottom track

Low Threshold Bottom Track – The brush seal is not as effective as the full rebate so we strongly recommend the rebated option. The low threshold option does not have a rebate for the door panel to close against so the seal is created by two rows of brush seals under the door panel. The low threshold option is 20mm lower so is only worth considering if the doors will not be installed into an exposed area.

WE RECOMMEND THE REBATED THRESHOLD FOR YOUR XP10 DOORS.

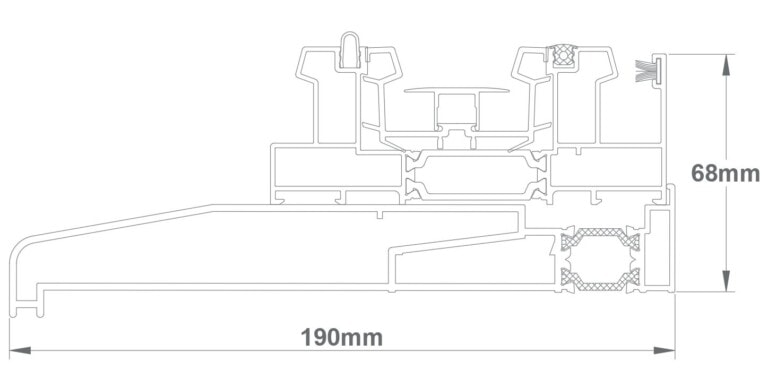

XP SLIDE LS25 THRESHOLD DETAIL

This drawing illustrates the depth & height of the XP Slide LS25 bottom track. This needs to be considered both when measuring for the doors but also preparing the opening prior to installation.

A solid base for our sliding doors

The XP Slide LS25 has a deep twin track, which is sat on a 190mm external cill, this gives an overall track height of 68mm. The doors outer frame needs to be sat 30mm back from outer brickwork so the base needs to be fully supported even over the cavity to make sure all the weight of the door is sat on a solid base. The base needs to be solid to take the weight of the doors. The doors also need installed onto a base that is completely level, this can be achieved by using packers. The doors also need to sit on top of a damp proof membrane. The membrane needs to be properly installed before the installation can take place.

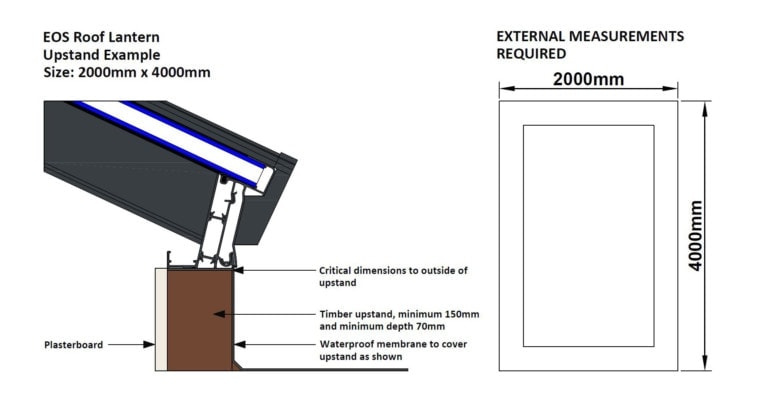

The upstand for our roof lanterns & skylights

Both our flat skylights & roof lanterns need to sit on a timber upstand to meet building regulations. The drawings below illustrate the upstand required for our EOS roof lanterns. The upstand for our flat rooflights needs to be constructed slightly differently with a five degree pitch to ensure rainwater runs off the rooflight. You can find an example drawing of the required upstand for our skylights below.

upstand for eos roof lantern

Our EOS roof lantern can enhance any flat roof within a home, but the property needs preparing specifically for this impressive roof lantern product. The roof lantern itself will sit on a timber upstand that needs creating before the roof lantern can be installed.

The timber upstand (often referred to as the ‘kerb’) needs to be a minimum height of 150mm to comply with building regulations and we recommend that it is manufactured to a minimum depth of 70mm. When you order your EOS roof lantern you will receive an easy to understand drawing with instructions on how to build the perfect sized upstand for the roof lantern that you have ordered.

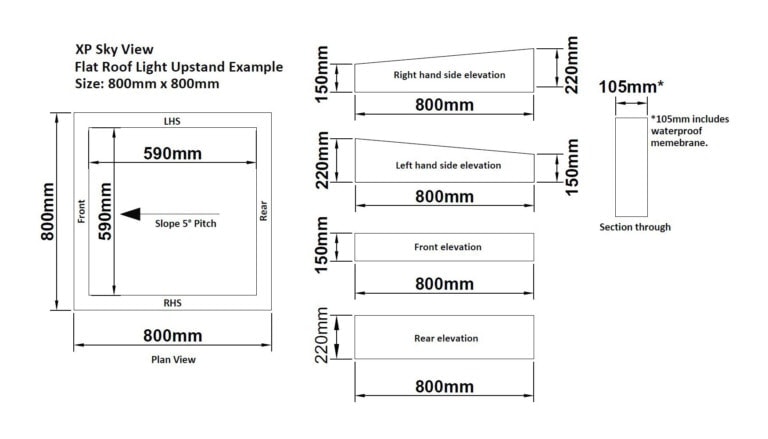

upstand for flat rooflights

The flat skylight needs to sit on a timber upstand with a five-degree pitch.

The upstand needs to be a minimum of 150mm high to satisfy building regulations and a minimum 80mm thick for the rooflight to sit on. Upstands play an important role in ensuring your new skylight sits and fits well. They are the frames that a skylight sits on, creating enough height from the roof surface and enough pitch for the water to run off. Upstands are vital as skylights are not meant to be submerged or have standing water or snow on them.

When you place your order with Express Bifolds Direct we will e-mail the required information to build the correct sized timber upstand for the sized roof that you have ordered.

More information on our specific product pages

You can find more information about our products on the specific product pages plus via the various help icons as you’re ordering the products themselves.

If you’re unsure or can’t find the specific information you’re looking for then don’t hesitate to contact us on [email protected].